ECERC

Energy

LNG cold energy recovery system

Today the world energy market is in great transition and the demand of clean energy such as liquefied natural gas (LNG) increases rapidly. Using LNG for road and marine transport could reduce oil demand and decrease toxic engine emissions than traditional fuels. LNG production consumes a huge amount of energy around 850 MJ (230 kWh) per ton when natural gas is refrigerated to -162°C and it is stored in the form of “Cold Energy”.

Valcon with partners have find a solution for recovering LNG cold energy and have developed a new flexible LNG cold energy system with fully utilization into LNG regasification process. This novel LNG cold energy recovery system is integrated in special insulated marine container which has mobility for transferring in different location.

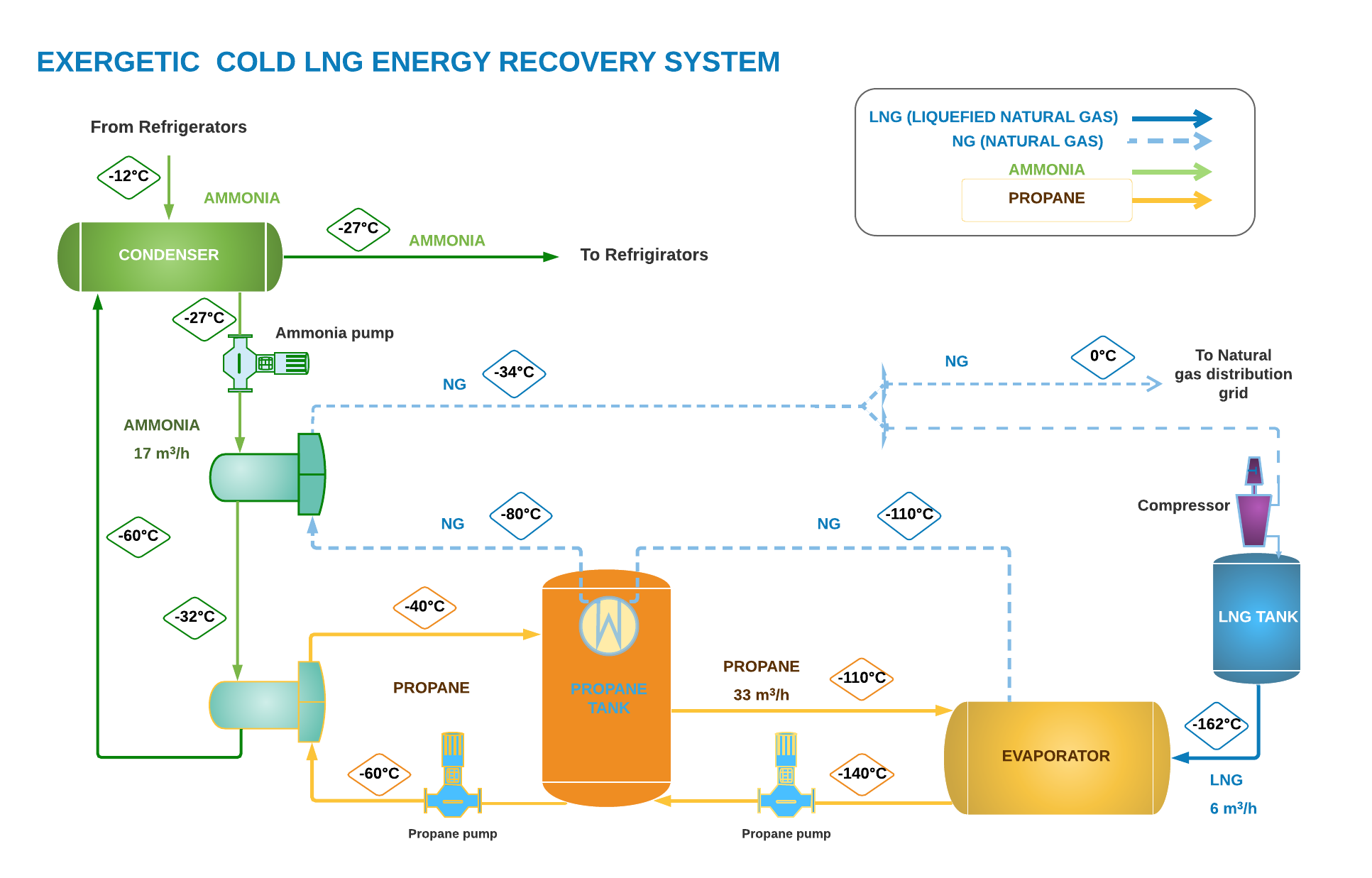

The system is designed to provide LNG as cryogenic fluid to refrigeration process. Recovering LNG cold energy during regasification process two coolants are provided. The first coolant propane (-60°C) is supplied to recover LNG cold energy during LNG evaporation process, where LNG transfers to gaseous state (-110°C) and LNG temperature changes is from -162°C to -110°C. After LNG evaporation, condensed propane (-140°C) is used to chill second coolant ammonia which is supplied for refrigeration process. Coolant Propane runs in a closed circuit and it is circulated by constant speed pumps. The coolant ammonia is circulated closed loop which is chilled by LNG vapor below -32°C and propane below -65°C. After ammonia condensation, the part flow of natural gas is compressed and sent back to LNG tank and the rest of the flow is supplied to the gas distribution system. This LNG cold energy recovering system decreases the size of compressors in refrigeration process reducing operational power, that leads to energy conservation. The simplified scheme below describes the principle of system working.