LNG for road transport

Road transport

Along with the supplies of liquefied natural gas, we offer attractive terms and conditions for delivery of infrastructure required for the final use of the gas. LNG terminals offered by the company allow for regasifying liquid phase or fueling of vehicles/ships.

Cryogas

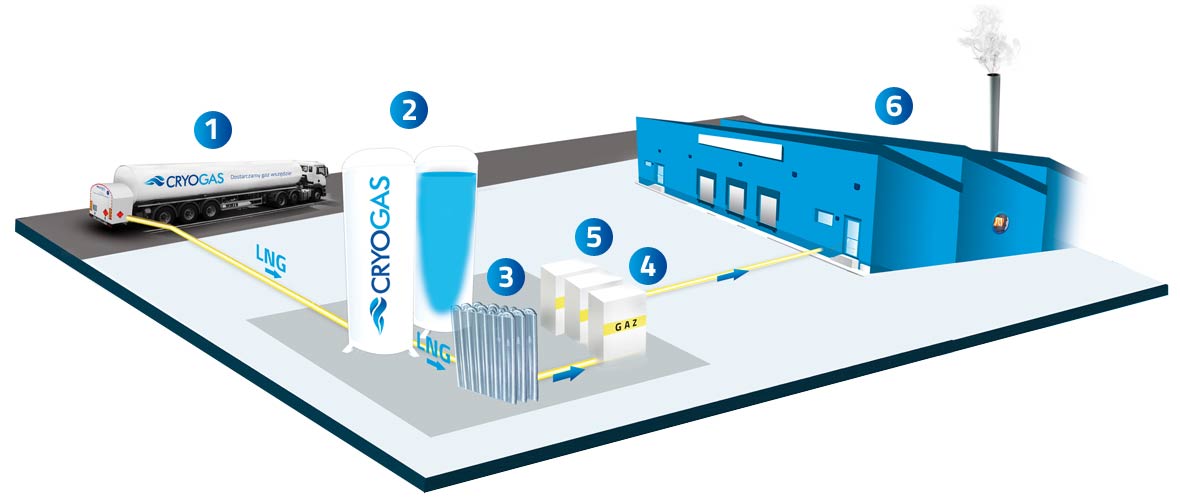

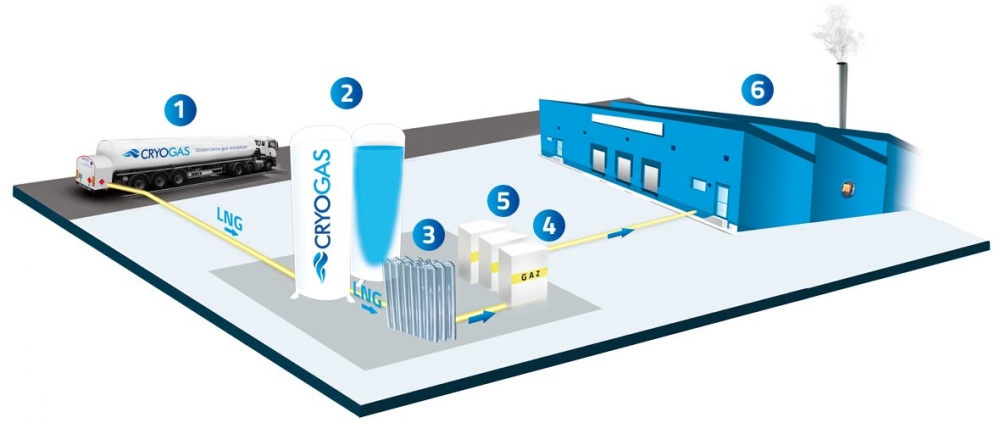

1. Cryogenic tanker truck

LNG is transported from a liquefaction plant to a regasification station in specialized cryogenic tankers, where low temperature of liquefied gas is maintained during transport. A typical tanker has a capacity of 18 tons, which after regasification produces 25,600 m³ of fuel in a gas form.

2. Cryogenic tanks

Used to store natural gas in liquefied form. The tank design allows the fuel to be kept at a temperature of -162°C. Cryogenic storage tanks have varied capacities, with 60 m³ being the most common one. Such a tank can hold max. 32,400 m³ of fuel in gas form. Technologically, it is possible to add more tanks to the LNG regasification station to have a larger storage capacity.

3. Vaporizers

Used to convert the fuel from liquid to gas form. Designed to guarantee regasification capacity requested by the user, counted in m³/h.

4. Pressure reduction/measurement station

Measurement of gas fuel and gas pressure reduction is performed here. Pressure reduction can take place in the station or along a gas duct before a consumption point. Final decision will be individually made by a facility designer for each design.

5. Boiler room, odorizing room

LNG is odorless, therefore an odorizing installation is provided to enrich the gas with a characteristic odor.

6. Plant boiler room